Marabu - UV LED INK application on Glass and Plastics

UV LED INK application on Glass and Plastics

Application Creative - Screen Printing

- Digital Printing

- Pad Printing

- Liquid Coating

Ultra Glass UVGL

• Fast UV curing

• Printing on glass or coated surfaces

• Excellent adhesion without baking

• Good chemical resistance

• Hot stamping capability, achieving a glossy finish

•Heavy metal free

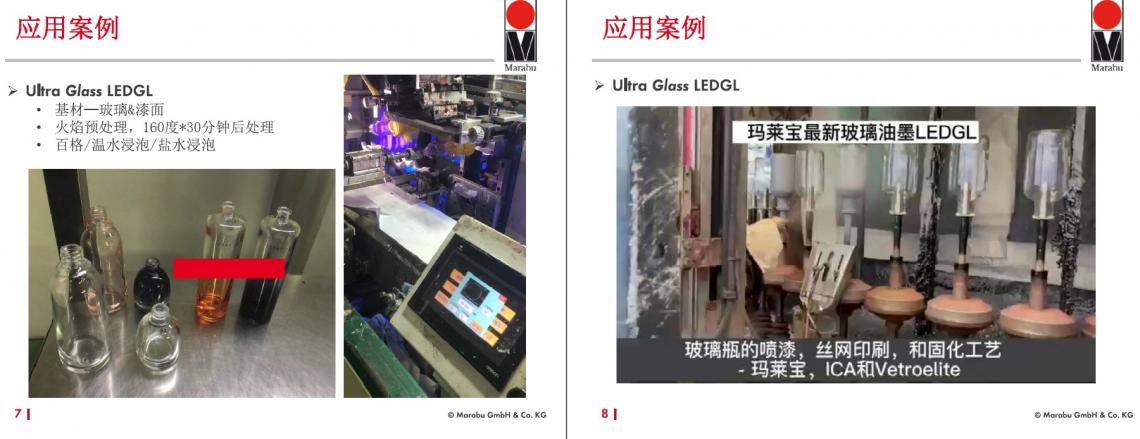

Ultra Glass LEDGL

• LED curing, saving 50% energy

• Printing on glass or coated surfaces

• Excellent adhesion without post-baking

•Excellent chemical resistance

UVGL Application case

• Flame pre-treatment, post-treatment at 160 degrees for 30 minutes

• Grid / Warm water immersion / Saltwater immersion

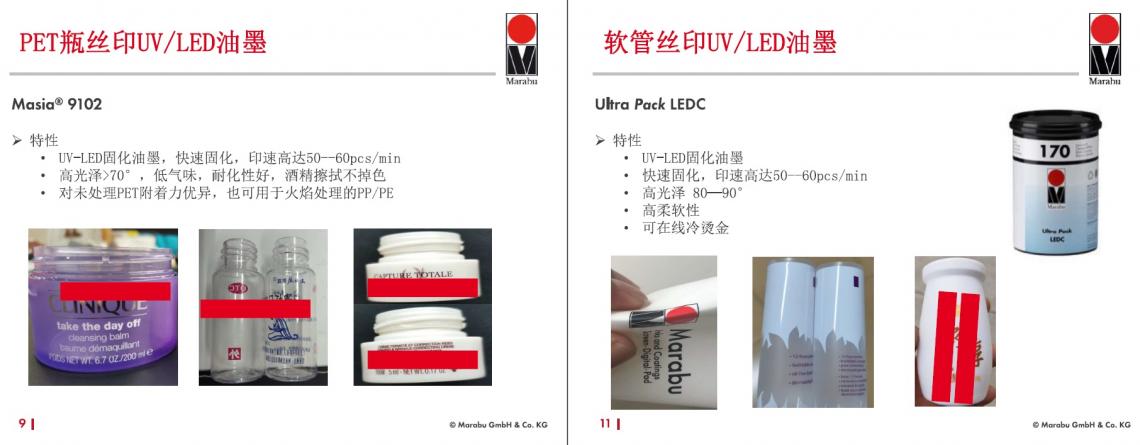

• UV-LED curable ink, fast curing, printing speed up to 50-60pcs/min

• High gloss >70°, low odor, excellent chemical resistance, alcohol wipe does not fade

• Excellent adhesion to untreated PET, can also be used on flame-treated PP/PE

Ultra Pack LEDC

Characteristics

• UV-LED curable ink

• Fast curing, printing speed up to 50-60pcs/min

• High gloss level of 80-90°

• High flexibility

• Can be used for in-line cold foiling

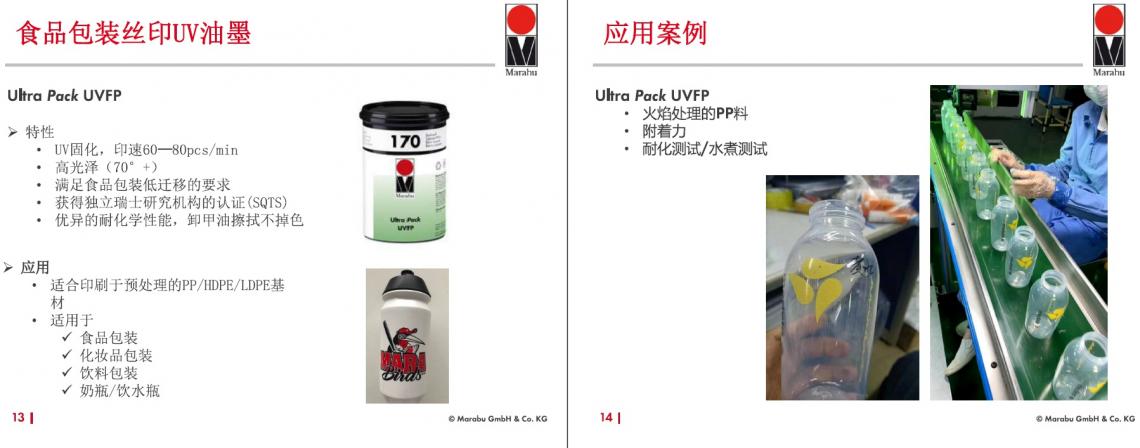

Ultra Pack UVFP

Characteristics

• UV curing, printing speed of 60-80pcs/min

• High gloss (70°+)

• Meets low migration requirements for food packaging

• Certified by an independent Swiss research institute (SQTS)

• Excellent chemical resistance, resistant to discoloration from nail polish remover

Application:

• Suitable for printing on pre-treated PP/HDPE/LDPE substrates

• Suitable for:

Food packaging

Cosmetics packaging

Beverage packaging

Milk bottles/containers

Application:

• Flame-treated PP material

• Adhesion

• Chemical resistance test / Water boiling test