Ultra Pack UVFP - The UV ink with lowest migration rate in the world

Assessment of Ink Migration and Packaging Ink Migration Rate | Marabu offers you UV inks with the lowest migration rate in the world.

- What is ink migration

Ink migration refers to a phenomenon where substances such as pigments and additives in ink penetrate or migrate through packaging materials and transfer or seep into consumer goods such as food, pharmaceuticals, health supplements, and beauty products, causing contamination of the consumer products.

- The types of ink migration

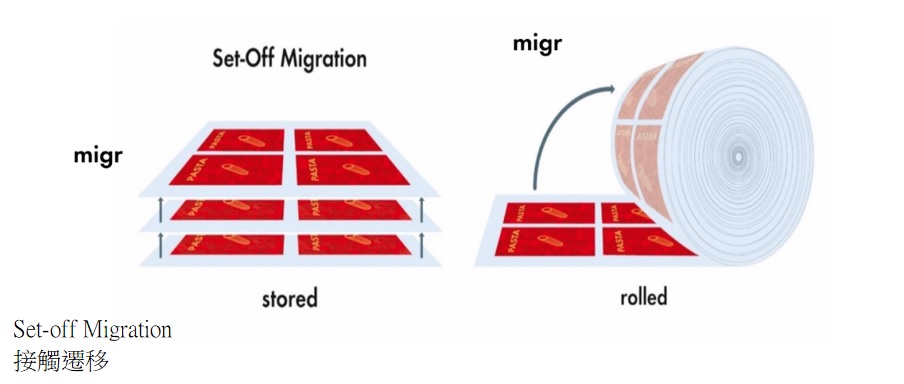

Set-off Migration

Ink migration occurs when ink transfers from the printed surface to an unprinted surface, which then comes into contact with a product, causing migration. During the process of rolling, stacking, and placing printed materials, ink may transfer to the unprinted side of the substrate under external forces such as high pressure. When the unprinted side of the substrate comes into contact with packaged food, potential migrating components in the ink may transfer to the food.

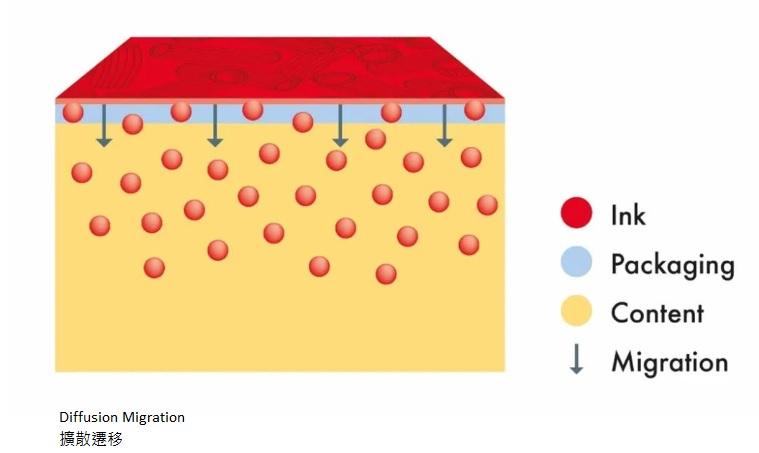

Diffusion Migration

Food packaging ink can migrate from the printed surface to the non-printed surface and come into contact with the product, causing migration.

The lowest migration rate in the world

Ultra Pack UVFP

Key Features:

High gloss, high chemical resistance, flexible ink layer, high reactivity, fast drying, water-resistant, steam-resistant, and resistant to various contents and chemicals.

Main Applications:

Food packaging, cosmetic packaging, beverage packaging, baby bottle packaging.

Suitable Substrates: HDPE/LDPE and PP.

Product Advantages:

1 The product label does not contain hazardous symbols, and the ink has a high level of safety.

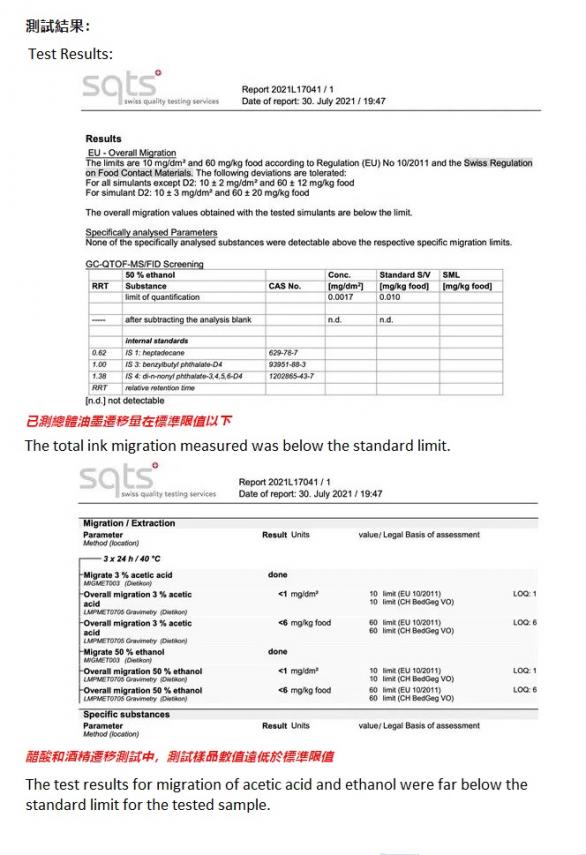

2 The ink has been tested by SQTS (Swiss Quality Testing Services), and the migration rate is less than 10ppb, which meets the requirements of EU 10/2011 (European Union-requirements for the safety of plastic materials in contact with food) and the Swiss Regulation on Food Contact Materials.

3 The product meets GMP standards, and Marabu can issue a GMP confirmation letter based on EUPI and FCM standards.

4 The ink complies with Nestle's Packaging Ink Guidelines.

5 The raw materials are carefully selected, and all raw materials used are included in the Consumer Product Electronic Data Exchange Regulation (SR817 .023.21).

6 BPA Free.