Marabu ink Products - Special Effects Part 2

Different visual and tactile effects can pique customer interest, while functional effects can increase product safety. Screen printing and Pad printing can achieve these effects.

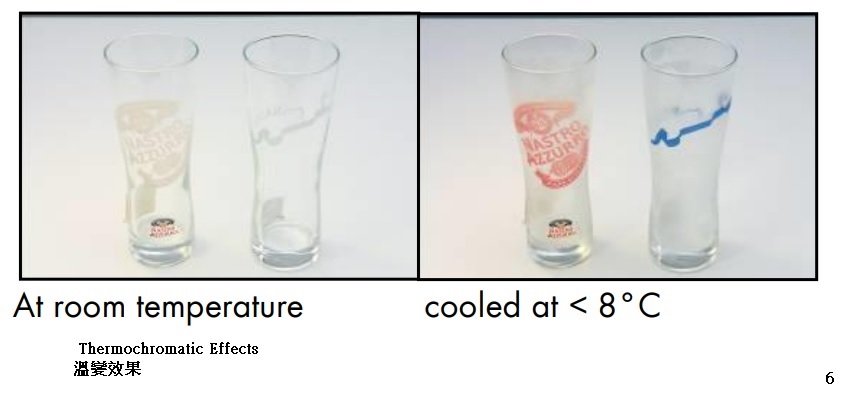

6.0 Thermochromatic Effects

These pigments change colour under the influence of temperature, typically as a reversible, but also obtainable as an irreversible effect. Variations are offered by selecting specific temperature ranges and by differing colour shades. It is possible, for example, that a wine label indicates a specific colour when the desired drinking temperature has been reached. This class of pigment can be offered upon request for solvent based and UV-curable Screen and Pad Printing ink series.

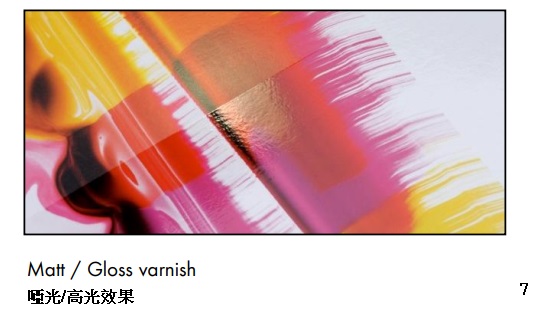

7.0 Matt, Structure, and Gloss Effects

Matt, Structure, and Gloss Effects Matt, structure, and gloss effects are a domain of Screen Printing, e.g. for labels or membrane switches. For a large number of applications Marabu offers various effects. Gloss, matt, and structure varnishes can be printed alone, combined for contrasting effects, or even mixed to create customised levels.

7.1 Matt

Matt surfaces have a very noble appearance due to their optical irregularity, offering diffuse light scatter. Furthermore, they are usually less sensitive to fingerprints than glossy surfaces. Marabu’s universal matt varnish is UVLM 2, as well as products in several other ink systems ending with the number code “913”

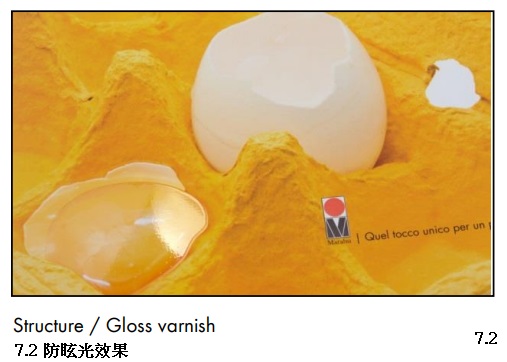

7.2Anti-glare effect

Typical Screen Printing applications for structured layers are membrane switches or automotive speedometers. Due to their hard and therefore almost scratch-free surface, UV-curable varnishes are predestined for these applications.

7.3 Gloss Effects

In the modern packaging and give-away markets, a very noble effect is attained via “spot-varnishing” which combines high-gloss coatings with matt surfaces. To achieve this effect, the resulting gloss level of an ink or an overprint varnish will be determined by the transparency of the binder, the additives used for the formulation, as well as by the printed ink film thickness and roughness of the substrate surface. High-gloss effects are a typical domain of screen printing. The best effect can be achieved with UVcurable ink systems. Marabu’s universal gloss varnishes are UVLG 1, UVLG 5 and UVLG 6; as well as products ending with the number code “910” in several other ink systems.

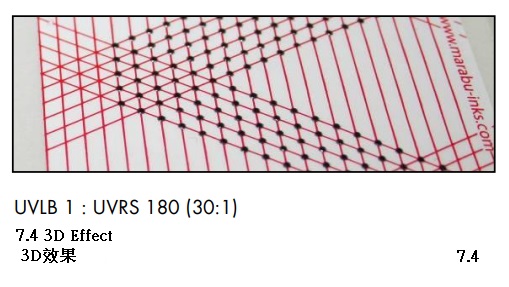

7.4 3D Effect

3D effects are well-known from dome-coating. Screen printing is used to achieve symbols or graphic characters with a thickness of 30 - 250μm. The resulting character is clearly perceptible and usually transparent as known with the triangular product safety symbol, Braille printing, or other graphical effects. By adding very little of a basic shade, the transparent Braille varnishes may also be coloured, as our example shows:

8. Writeable Inks

Writeable Inks (only realisable with Screen Printing) usually have a matt and quite rough surface, are very resistant, and can be used for different applications.

9. Scent Effects

Everyone has seen and probably smelled test perfume strips included in magazines. A fragrance is released when rubbing the surface. The resulting friction causes the extremely tiny scent capsules to burst and liberate their fragrance. The manufacturers of such raw materials offer varying scents which can in some cases be used in screen printing, as long as the compatibility has been confirmed. During printing, it is particularly important to ensure, however, that the ink is not exposed to high pressure or abrasion from the squeegee as the scent capsules would then prematurely burst and cover the printing room instead of the intended product.