Marabu ink Products - Special Effects Part 1

Functional effects can increase the safety of products. These effects can be achieved through screen printing and pad printing.

1 Metallic Effect

The different color tones, particle sizes, gloss levels, adhesion, quality, and price of metallic effects provide endless possibilities for printing. In addition, adding transparent gloss oil can expand the printing surface on materials such as gold, silver, and copper. Screen printing can easily adjust the ink thickness by selecting the appropriate mesh size, with a film thickness of up to 20μm. Pad printing can also achieve these effects.

High Gloss Metallic Ink

High gloss metallic ink produces a pattern with a high gloss appearance and good abrasion resistance. The gloss level and price determine the different qualities, and it is suitable for pad printing or screen printing.

Stampable Metal Material

In some solvent-based ink systems, existing metallic tones can be chosen as standard tones, such as the Marabu color system with codes ending in 191-193 and 291-293 for high gloss versions. If there are no standards, stamp-ready metallic materials can be provided according to requirements.

UVGL Hot Stamping Ink

Precious metals are often used for decoration in high-end products. Despite continuous improvements, the printing effects of gold and silver ink can never achieve the expensive precious metal appearance without high-temperature baking. However, Marabu provides the perfect solution with UVGL ink combined with hot stamping: achieving better presentation at lower cost.

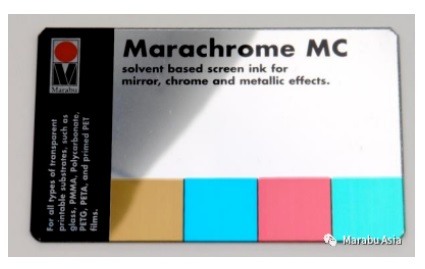

2. Mirror Effect

In the past, mirror effects could only be achieved through expensive processes such as glass silver plating. Mara® Chrome MC screen printing ink makes it easy for you to achieve this effect. The stunning golden, bronze, or colored metal effects can be achieved through Marabu SR ink.

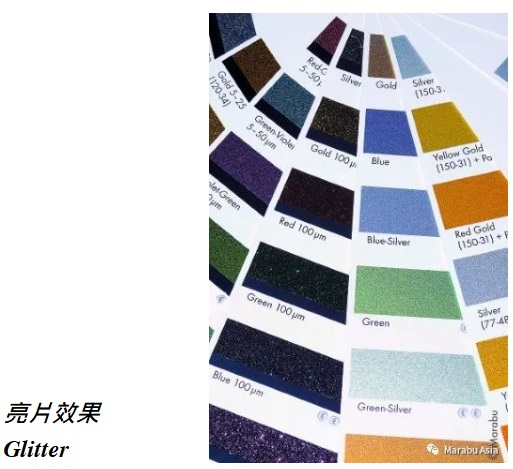

3. Glitter Effect

Glitter is a coating of polyester pigment, and therefore has a very special and shiny glitter effect. Typical application areas include graphic effects in the packaging or credit card industry. Depending on the requirements, the sparkling effect can be achieved through UV-curing inks or solvent-based inks.

4. Pearl Effect

Pearlescent pigments are inherently very transparent and can have significant shadow variations depending on the color of the substrate. These pigments are most effective on black substrates, but can also achieve unparalleled effects on bright substrates. Silver-white pigments have different hues and sizes. The angle-dependent effect refers to the change in color based on the viewing angle and the angle of incidence of the light. Highly bright pearlescent pigments have vivid colors and luster, and they come in different colors to choose from.

If chosen correctly, pearlescent pigments are suitable for solvent-based screen printing and pad printing inks, as well as UV-curable screen printing inks. Although there are many types of pigments that require fine-tuning based on requirements, we provide customized solutions.

5. Phosphorescent Effects

Phosphorescent ink:

Luminescent products can absorb and store short-wave ultraviolet light, which can be released in the dark to achieve a glow-in-the-dark effect. This effect is well known in safety technology, such as for emergency exit signs or dashboard displays. The length of luminescence depends on the amount of light energy absorbed and the size of the used filament.

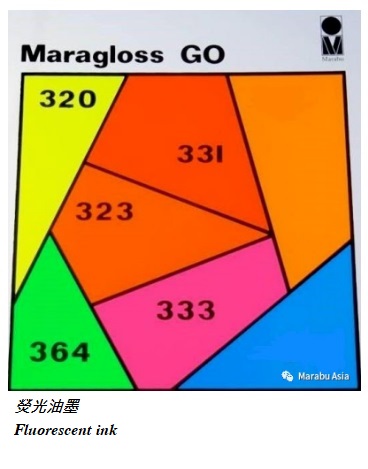

Fluorescent ink:

This effect, commonly referred to as "fluorescence," gives a very strong and bright feeling. Due to the low opacity of these pigments, printing on white substrates produces the best results. Fluorescent ink is suitable for short-term outdoor use, as the inherent chemical properties of the pigment (the effect emitted when the pigment fades) provide lower ultraviolet stability.

UV sensitive ink:

Ultraviolet (UV) active pigments are not visible in sunlight. The colors can only be seen under strong ultraviolet light sources (black light). Therefore, these effects are mainly used in industries with high requirements for product safety (such as the pharmaceutical industry). Some pigments on the market provide effects from transparent to yellow or blue. Depending on the requirements, Marabu provides solvent-based inks or UV screen printing inks.