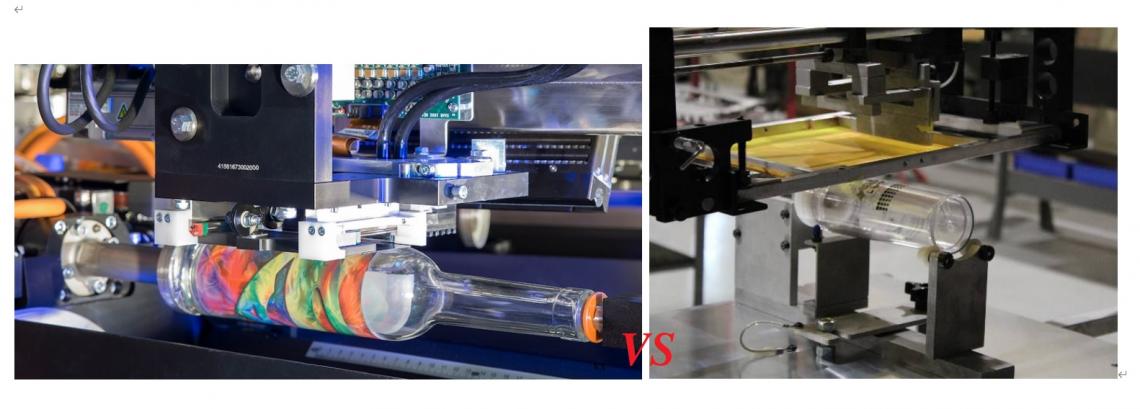

Screen Printing Ink vs Digital Printing Ink - Glass printing application

Each printing process has its own outstanding features and shortcomings. Therefore, the combination of different technologies with their own strengths is more and more popular in the market. For glass bottle packaging, different shapes, different visual and tactile effects, metallic luster, etc., are the highlights of packaging design and even product highlights.

Screen Printing |

Digital Printing |

| Each printing process has its own outstanding features and shortcomings. Therefore, the combination of different technologies with their own strengths is more and more popular in the market. For glass bottle packaging, different shapes, different visual and tactile effects, metallic luster, etc., are the highlights of packaging design and even product highlights. |

Digital printing conquers the world with only four colors! Only CMYK (cyan, yellow, magenta, black) and white are required, and any color can be realized by CMYK four colors. Customers do not need to prepare warehouses, and do not need to add curing agents or additives. In addition, digital printing can achieve a variety of effects, such as embossed feeling, combined with visual and tactile sensations, and finer line rendering, which is very suitable for printing high-definition embossed patterns (thickness can reach 3mm). |

| High edge definition, intricate designs, even for screen printing. Moreover, it can also realize variable temperature color (different colors according to different temperature ranges), which not only has aesthetic significance, but also has the function of temperature control reminder (for example, the best tasting temperature of wine). In addition, the glass bottle screen printing speed can reach up to 300 bottles per minute, which is very efficient. | It can be printed according to demand, customized and personalized. There is no requirement for shape, and there is no fear of concave and convex surfaces. Precise printing of edges and radians can be achieved, so that the design of the package is not limited by size and position, and can be extended to any part of the package. Digital printing can also realize the overall pattern from top to bottom, whether it is 3D relief or metal colorful, it is omnipotent. High resolution and rich colors. |

| Our hot stamping effect, high color saturation. Screen printing and bronzing technology can be regarded as old friends in the world. At present, under the environment of energy crisis, energy saving is an important topic. For traditional ceramic glass ink (after the screen is heated by the oven, the ink on the surface of the product needs to be sintered at high temperature to ensure that the ink is not easy to peel off), our UV solution ( By using ultraviolet light to cure immediately after printing to ensure ink adhesion and multi-color overprinting), energy saving is 75%; UVLED scheme, energy saving is 98%, so less carbon footprint. |

Digital printing can also achieve various metallic effects! Digital printing is a non-contact surface printing process, which is a good supplement to the patterns that cannot be completed by screen printing, especially for printing on concave-convex and uneven surfaces. |

The combination of technology creates infinite possibilities. The combination of screen printing and digital printing has become a new trend.

Whether it is fine lines and text logos, or complex and realistic patterns, it can be realized by screen printing + digital printing!

Marabu provides a complete solution for glass curved surface printing: screen printing, pad printing, digital printing, bronzing effect...

For more detailed product information, welcome to consult us!