Screen Lamination Solutions

Screen Lamination Solutions

Water Based Screen

- Apollo water‐based screen inks remain open on the screen giving excellent press stability and ease of

use. These inks run well with the same dryer configuration as their solvent‐based counterparts.

- These inks give the dual advantages of reducing V.O.C emissions while maintaining high lamination bond

strengths across various substrates.

- A full range of water‐based inks is available in Opaque White, Golds, Silvers, Metallic’s, Pearls, Adhesives

and Primers.

UV Screen

- These inks have been formulated for the production of laminated plastic cards. They deliver exceptional

bond strengths without the risk of cracking and can be used with high‐speed printing.

- Apollo U.V. inks maintain very low VOCs and are RoHS compliant. They have a lower build than

conventional Solvent screen inks, perfect for use with coated & uncoated overlays. These range of inks are

ideal for printing onto P.V.C. material. Superlam inks are available in Colours, Metallic, Pearls and

Varnishes.

Solvent: Advantages & Disadvantages

Advantages:

Endless Colour and Specialized inks.

Exceptional press performance.

Exceptional Bond Strength greater then ISO standards.

Very versatile across all PVC substrates.

Disadvantages

Slight odour.

VOC consideration.

Storage and shipping considerations.

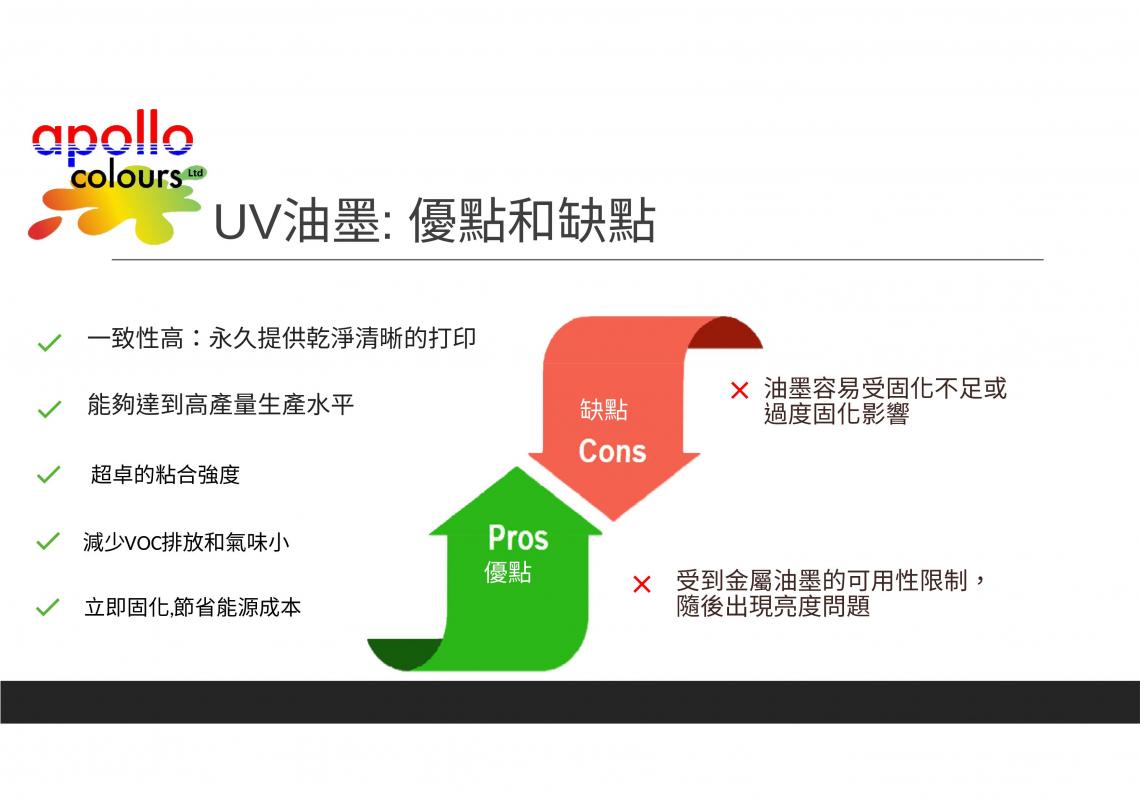

UV: Advantages & Disadvantages

Advantages

- High level of consistency: always delivers clean and crystal‐clear printing.

- Able to reach high level of output in production levels.

- Exceptional bond strength.

- Reduced VOC emissions and low odour.

- Immediate drying, saving energy cost.

Disadvantages

Sensitive to under or over curing

Availability of metallic inks are limited followed by brightness problems.