Stencils, Mesh Preparation

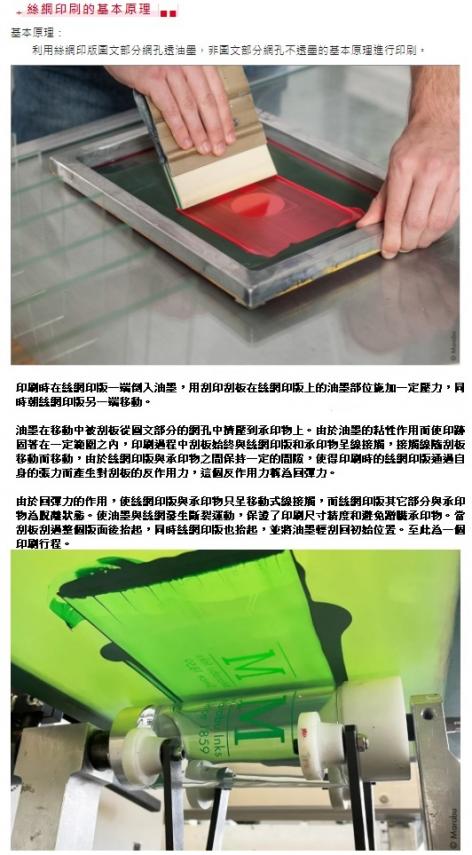

Screen printing consists of five elements: Stencils, squeegee, ink, printing table and substrate

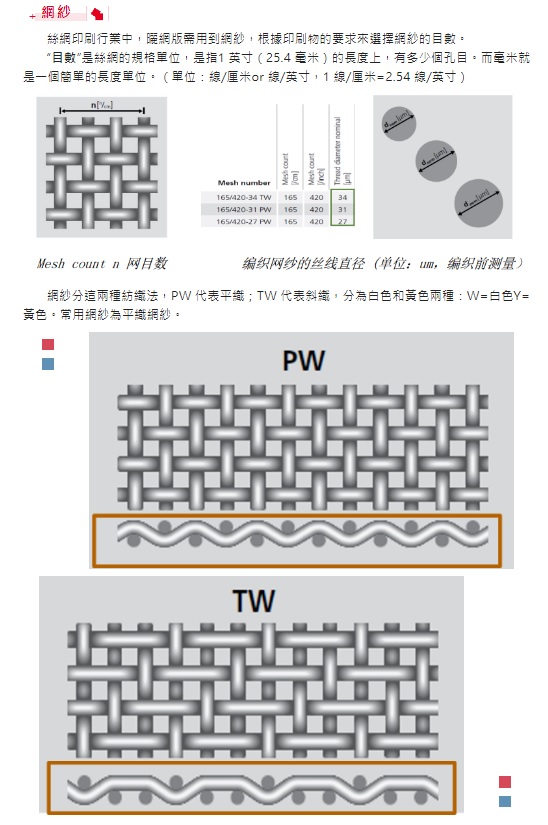

"Mesh" is the specification unit of wire mesh, which refers to how many meshes there are in a length of 1 inch (25.4 mm). A millimeter is a simple unit of length. (Unit: line/cm or line/inch, 1 line/cm=2.54 line/inch)

Screen making process

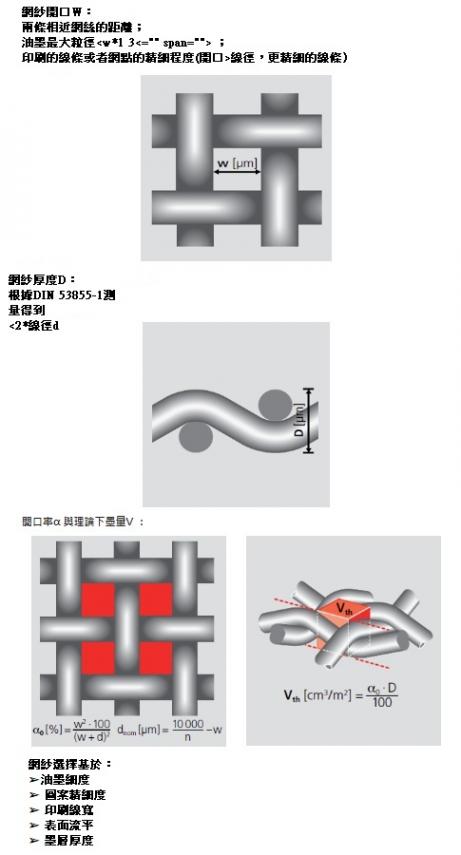

Step 1: Stretching

Pay attention to tension and stretching angle (0°/15°/22.5°)

Step 2: Degreasing

Purpose: to improve the adhesion between the photosensitive adhesive and the mesh

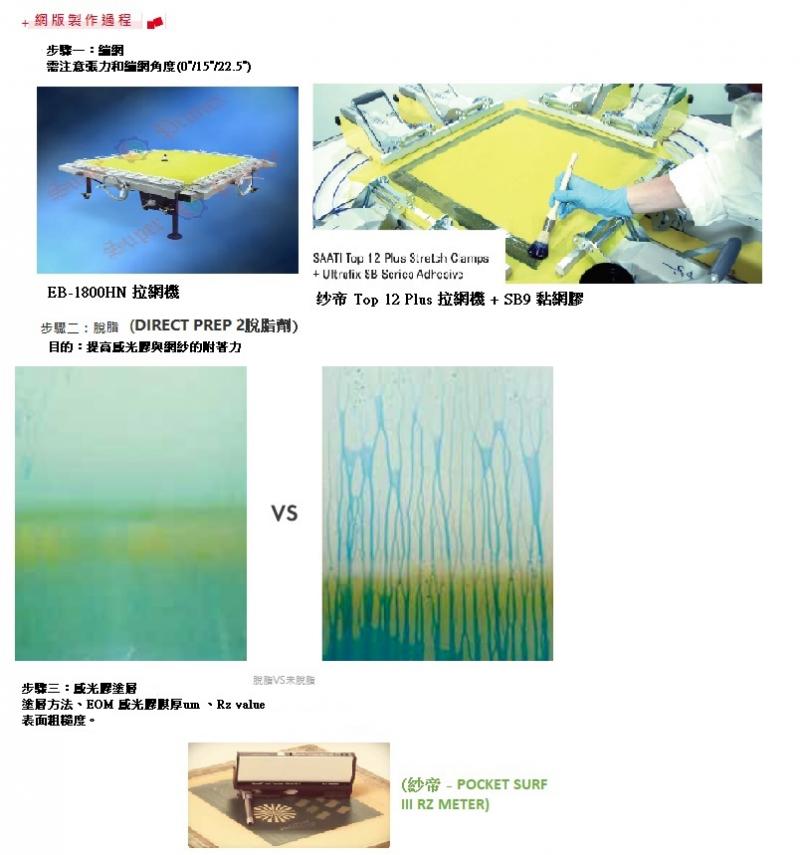

Step 3: Coating Emulsion

Coating method, EOM photoresist film thickness um, Rz value Surface roughness.

Step 4: Exposure

UV curable emulsion

Reasonable control of exposure—exposure calculator;

Exposure method: traditional mercury lamp VS CTS

Step 5: you should wash the stencil with a power washer to remove the remaining emulsion. This will remove the areas related to the design so that the ink can pass through like with a stencil.